Pick and Pack is the most common operation in order fulfillment and a popular service offered by many Fulfillment Centers. It is a process by which the individual components of an order are gathered from a high velocity pick location or master cartons (Picked) and then placed into a box or envelope addressed to a specific order (Packed). The Pick and Pack process sounds simple, but it requires a high degree of coordination, organization and attention to details to run efficiently and accurately.

Pick and pack is:

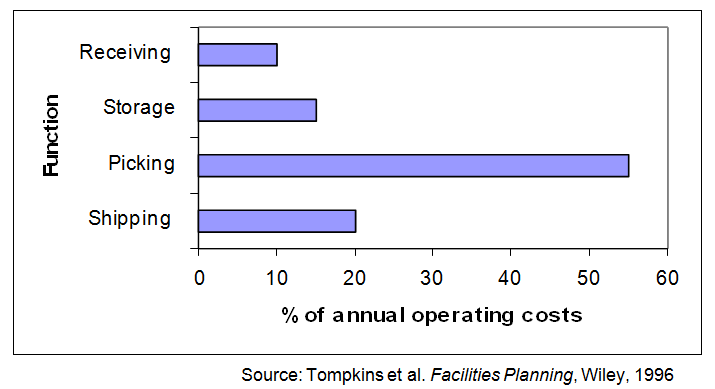

- most laborious in a typical warehouse

- up to 55% of warehouse operating cost

- direct influence on order accuracy and delivery time

- 50 % of the total order-picking time spent on unproductive traveling

Pick and pack methods should be considered for order fulfillment efficiency.

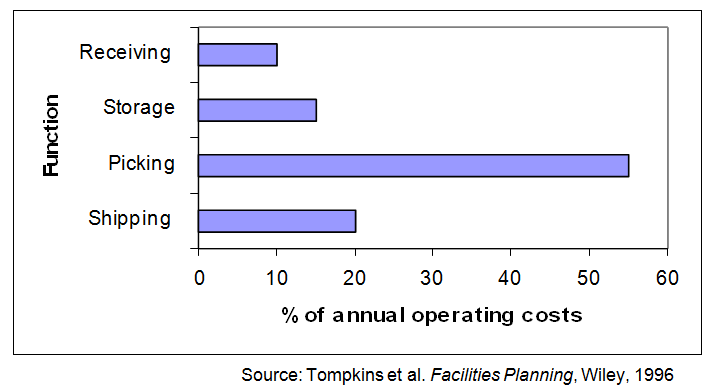

- Routing – determines the sequences and routes of picking

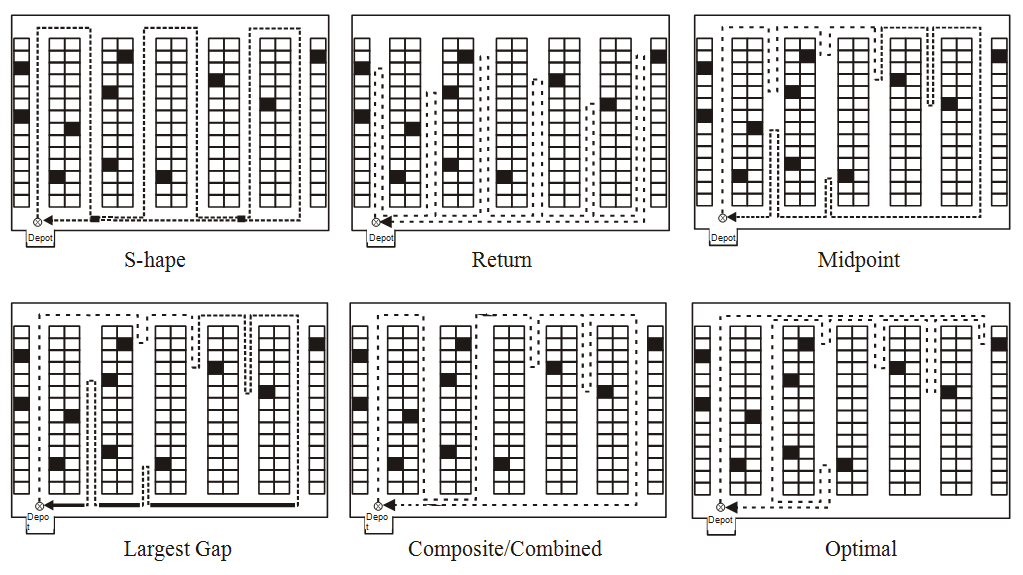

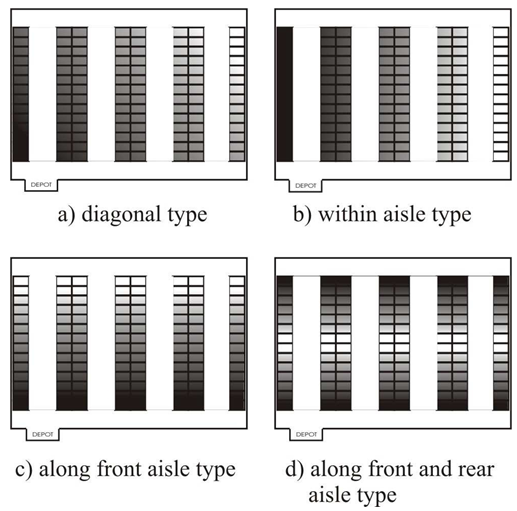

- Storage – assigns items to inventory location based on specified rules (velocity, logistics unit, etc.)

- Order batching – groups two or more orders for picking purpose

- Performance – considers size of layout of warehouse, profiles of orders, labor capacity, material handling equipment, etc.

- Combination of the above.

Routing methods:

Storage methods:

- Most frequently accessed items in the locations nearest to the shipping area.

Contact Iggnition for more information about Pick and Pack.