The first research towards defining order fulfillment strategies was published by Mather (1988) and his discussion of the P:D ratio, whereby P is defined as the production lead-time, i.e. how long it takes to manufacture a product, and D is the demand lead-time, i.e. how long customers are willing to wait for the order to be completed. Based on comparing P and D, a firm has several basic strategic order fulfillment options:

- Engineer-to-Order (ETO) – (D>>P) Here, the product is designed and built to customer specifications; this approach is most common for large construction projects and one-off products, such as Formula 1 cars.

- Build-to-Order (BTO) or Make-to-Order (MTO) – (D>P) Here, the product is based on a standard design, but component production and manufacture of the final product is linked to the order placed by the final customer’s specifications; this strategy is typical for high-end motor vehicles and aircraft

- Assemble-to-Order (ATO) – (D<P) Here, the product is built to customer specifications from a stock of existing components. This assumes a modular product architecture that allows for the final product to be configured in this way; a typical example for this approach is Dell’s approach to customizing its computers.

- Make-to-Stock (MTS) or Build-to-Forecast (BTF) – (D=0) Here, the product is built against a sales forecast, and sold to the customer from finished goods stock; this approach is common in the grocery and retail sectors.

- Digital Copy (DC) – (D=0, P=0) Where products are digital assets and inventory is maintained with a single digital master. Copies are created on-demand, downloaded and saved on customers’ storage devices.

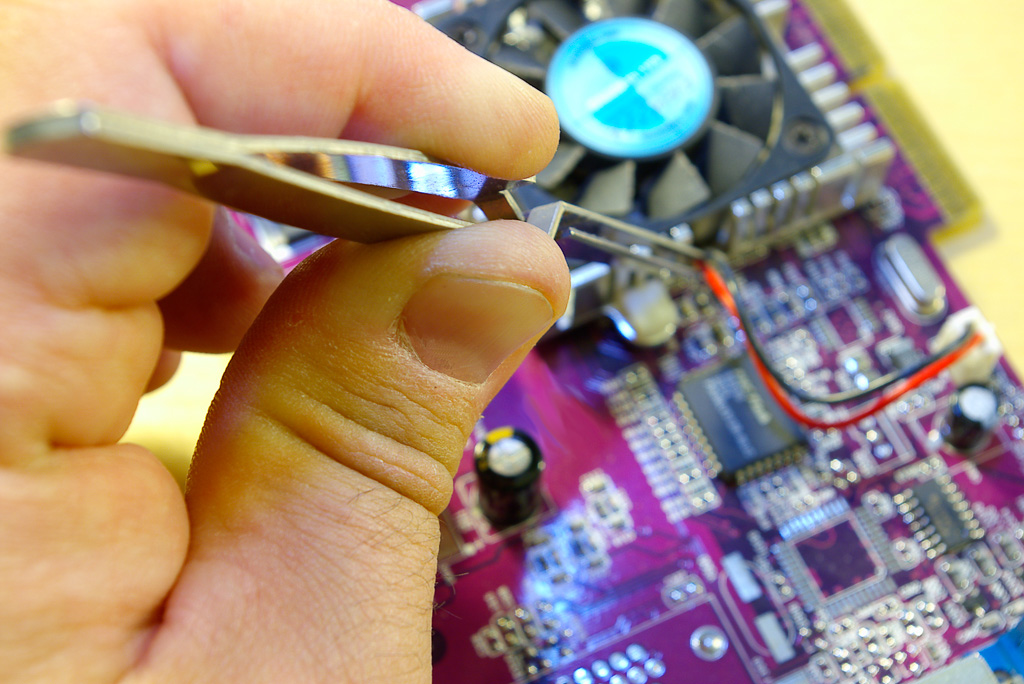

Manufacturers typically use the term assembly while wholesaling industry (comprised of 3PL and distribution companies) use kitting. You are either combining raw materials to create a finished good, or combining already finished goods into a larger group. Even if you have raw goods, you can still kit for assembly. Kitting is for anyone who wants to combine group items together, build a product, or make a master item.

While it helps companies to keep inventory levels as low as possible, ensure that materials and products are available for production and customer delivery, as well as plan manufacturing activities, delivery schedules and purchasing activities, kitting can deliver even more benefits:

Facilities

By reducing stock and using, kitting can save space that is normally allocated to manufacturing or inventory.

Operations

Kitting can positively impact the efficiency of your operations. By eliminating the need to supply individual component containers, you can reduce material delivery to workstations. Similar efficiency is available if you are a manufacturer or distributor that uses machinery to assemble. You don’t have to stop the lines due to part shortages or need to search for parts. Another benefit is that your shop floor can be cleaner because you’re using fewer containers with more individual items in each, rather than a container for every component.

Competitiveness

Two areas where kitting clearly adds economic value is by

- Increasing throughput in pick and pack and manufacturing operations, and

- Reducing Work in Progress (WIP) inventory. (WIP bottlenecks at or near the production lines can be reduced, or at least better controlled).

By storing primary components and subassemblies in a centralized storage area, kitting can reduce WIP inventory at the point of assembly.

Flexibility

Since components are not stored or staged at the points of assembly, facilities have greater flexibility in changing assembly lines as well as the products they assemble.

Labor

When kitting is part of the process, assembly workers usually spend more time assembling and less time walking around searching for components. The value-add time contributed by assemblers is therefore maximized. Another benefit that researchers who have academically studied kitting operations have noticed is that new staff training costs and acclimation periods are reduced.

Quality

Kitting can have a very positive upside when tracking product and part quality. Part damage, due to less handling will usually drop. This is especially important if the parts are either expensive or perishable. Another area where quality improves is tracing and correcting defects. Kitting provides the opportunity to have quality control verification earlier, reducing the possibility of wrong parts or incorrectly assembled components being used in the final product.

In summary, kitting and assembly is the process of converting existing raw materials and parts into a product. All of the parts used in the creation of the product are removed from inventory to make a new final product.

Iggnition’s Kitting and Assembly software includes Bill Of Material (BOM), Work In Process (WIP) inventory, back flush, quality control, and labor management. Contact Iggnition for more information.